I redesigned the packaging for our new 20W and 65W USB plugs, moving from blister packs to fully printed cardboard boxes. This included creating a new structural design, refreshing the graphics, and working with suppliers to ensure factories could produce the packaging accurately.

Switching to cardboard reduced single-use plastic, improved shelf appeal and gave us more space for clear product information. It also streamlined shipping and storage, making the packaging more sustainable, practical, and brand-aligned.

USB Chargers

packaging solution project

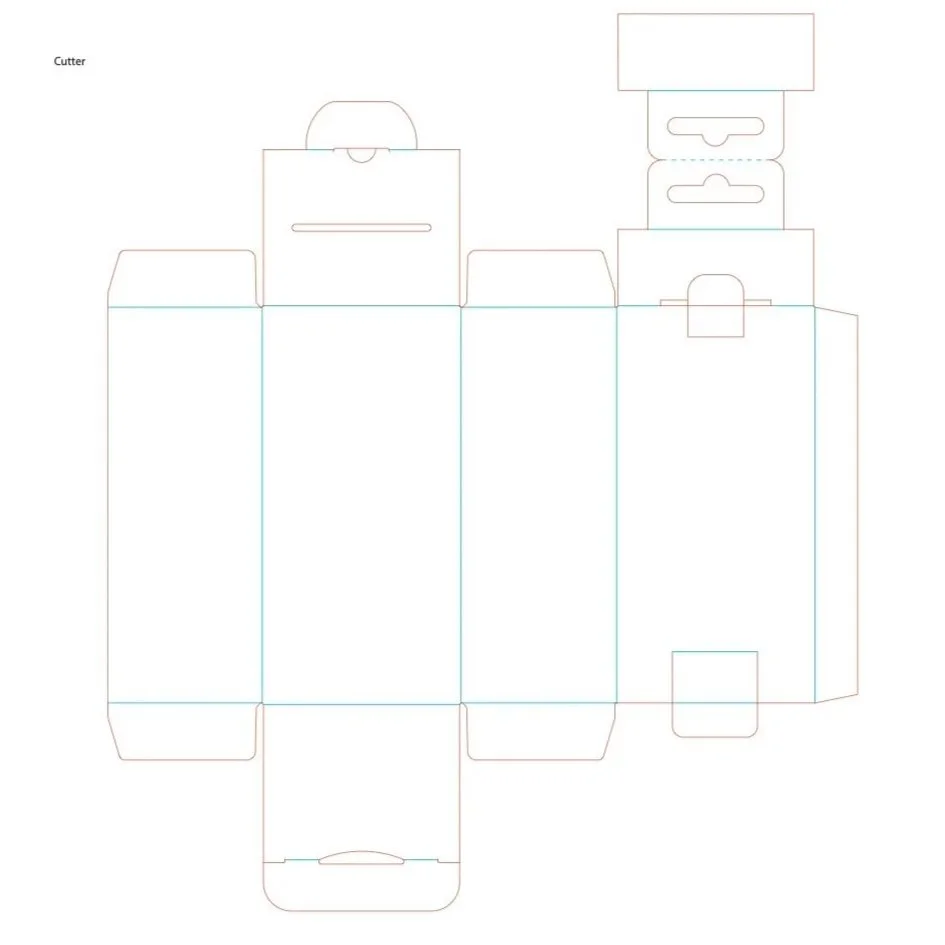

This project began with a full review of the existing blister packaging to understand its limitations in sustainability, shelf impact, and overall look and feel. With the dieline sent over and made by the supplier, I initiated designing the artwork. This included mapping out front-of-pack hierarchy, updating product imagery, refining colour consistency and organising technical details such as barcodes, warnings, certifications, and rear of pack translations. I worked closely with suppliers to confirm cutter guide tolerances, ensure crease lines matched their tooling capabilities, and verify that finishes like spot UV or embossing would behave correctly on the chosen board.

Prototypes were then produced and tested for structural strength, product fit, colour accuracy, and ease of assembly. Based on supplier feedback, I made technical adjustments to improve foldability and reduce waste during production. After final approval, the dieline and artwork were released to the factories in China with detailed specifications. Throughout the process, I maintained communication with the suppliers to ensure smooth onboarding, correct execution, and consistency across all production runs.